International

Get Ready For The Next Supply Chain Shockwave

Get Ready For The Next Supply Chain Shockwave

By Eric Kulisch of FreightWaves

Concern is growing that the spread of COVID cases and city…

By Eric Kulisch of FreightWaves

Concern is growing that the spread of COVID cases and city lockdowns in China will have massive downstream effects for global supply chains that could dwarf previous disruptions since the start of the pandemic.

Last May, the huge Yantian container terminal at the Port of Shenzhen throttled down to 30% of normal productivity for a month to stamp out a handful of positive cases there. Hundreds of thousands of shipments that couldn’t enter the port accumulated in factories and warehouses, and many vessels skipped the port to avoid waiting seven days or more at anchor. It took weeks after the port reopened to clear the cargo backlog. The effects cascaded to the U.S. and Europe, resulting in port traffic jams, transit times triple the norm and missed retail deliveries for the holidays.

The difference this time is that an entire metropolis — and highly interconnected global trade center — is essentially shut down. Not since the initial 2020 COVID-19 outbreak in Wuhan have lockdowns been this extensive in China.

“It’s probably worse than Wuhan,” said Jon Monroe, an ocean shipping and supply chain expert who runs a consulting firm. “You’re going to have a lot of pent-up orders. It’s going to be an overwhelming movement of goods” that will drown shipping lines and ports once the lockdowns are lifted.

Freight is piling up

Twenty-five million people in Shanghai have been sequestered for 18 days. Chinese authorities this week slightly eased the restrictions, dividing the city into three categories based on previous screenings and risk levels. People can wander outside their apartment buildings but are encouraged to stay home in neighborhoods with no positive COVID-19 cases in the past two weeks. Those in high-risk areas must still shelter at home.

Spanish financial services firm BBVA predicts Chinese authorities will stick to the “zero-COVID” strategy and lockdowns until at least June. Other China observers say it could take even longer to meet China’s infection standard.

Shanghai is one of the largest manufacturing centers in China, with heavy concentrations of automotive and electronics suppliers. It is home to the largest container port in the world and a major airport that serves inbound and outbound air cargo. Exports produced in Shanghai account for 7.2% of China’s total volume and about 20% of China’s export container throughput moves through the port there, according to the BBVA report.

Most warehouses and plants are closed, nine out of 10 trucks are sidelined, the port and airport have limited function, shipping units are stranded in the wrong places, and freight is piling up.

More and more, the logistics impacts are rippling beyond the contagion epicenter.

Impacts spread beyond Shanghai

Export containers that were already at the Port of Shanghai when the lockdown started are making it onto vessels, but most goods booked on outbound vessels are stranded at warehouses because shuttle trucks can’t make pickups or deliveries.

Truckers require special permits, which are only good for 24 hours, as well as negative COVID tests to get in and out of the city or enter certain zones, according to logistics providers. Checking COVID certificates has led to huge traffic jams at the port.

The French logistics provider Geodis reports that truck drivers in the Shanghai area are being forced to wait up to 40 hours at certain highway entrances. Trucking rates have soared because of the limited supply, and shippers are waiting three to five days for cargo to get picked up, according to San Francisco-based Flexport.

Reduced manufacturing output, along with limited truck access to the port and airport, are causing a significant drop in air and ocean export volumes. Less demand is translating to lower freight rates.

In response to the lack of labor and cargo, air carriers have announced widespread cancellations, and some ocean carriers are skipping Shanghai port calls.

Several shipping lines have also begun offloading refrigerated containers at other ports along their voyage because the storage area with electric plugs is too crowded in Shanghai. Customers face extra port fees and delays routing the cargo to its intended destination. Maersk, the second-largest container vessel operator, said Thursday it has stopped accepting bookings to Shanghai for refrigerated cargo, some types of gas and flammable liquids.

More omissions are expected and liner companies may temporarily idle vessels or cancel some outbound Asia sailings altogether, according to Crane Worldwide Logistics and other service providers.

Asia-U.S. East Coast rates have fallen 7% since the outbreaks in March, said freight booking site Freightos, which also publishes an ocean rate index.

“But even if the lockdown persists and demand drops significantly, ocean carriers will likely reduce capacity which could keep rates from plummeting, just as they were able to do in the first few months of the pandemic when ocean volumes fell significantly but transpacific rates declined by less than 15% and were about level year on year,” it said.

The supply chain is backing up like water behind a dam. When water is released, the landscape gets flooded.

At Shanghai Pudong airport, ground handling companies are operating with skeleton staff.

Shanghai Eastern Airlines Logistics, a cargo terminal operator, ceased bulk loading of containers after a positive COVID case, which will further slow cargo processing, said Dimerco, a Taiwan-based freight forwarder. Airlines report that Pactl, which operates three other cargo terminals, has suspended acceptance of dangerous goods and temperature-controlled cargo because the warehouse is full.

Flexport said in a market update that 80% of commercial freighter services have been canceled and airlines are considering shifting operations to nearby airports. Qatar Airways announced that freighter flights will remain canceled until next Thursday, saying “the latest COVID-19 restrictions announced by local authorities limit our ability to operate flights in and out of Shanghai with sufficient cargo loads.”

Freight forwarders have been rerouting cargo to alternative airports such as Zhengzhou, Xiamen, Shenzhen and Beijing, as well as the Port of Ningbo, but those facilities are beginning to feel congestion effects themselves. Rates to ship from those locations are increasing.

Flights at Zhengzhou Xinzheng International Airport are reduced by 50%, according to Geodis. Most inbound cargo there is transit cargo to other cities, such as Shanghai — which is compounding backlogs because the cargo isn’t allowed to move to the final destination. That means logistics companies can only clear shipments that customers can pick up in Zhengzhou.

Dimerco advises that Zhengzhou airport is not accepting loose cargo – only palletized shipments – because of labor challenges. And it has just implemented a 14-day closed-loop program in which workers live on-site to minimize the potential for virus transmission, forcing the logistics provider to pivot again and reroute shipments to other airports, including back to Shanghai’s second airport – Hongqiao International.

Everstream Analytics, which helps companies manage supply chain risk, predicts U.S. and Canadian automotive assembly plants will quickly face delays and disruptions because the lockdowns will affect shipping of parts such as seats, tires, engines, bodies and brakes.

Ships delayed at port of Hong Kong and Yantian

Shipping schedules in South China are being impacted by irregular feeder vessels and large barge services, creating delays for transoceanic vessels at the ports of Hong Kong and Yantian, according to a situational update from supply chain data platform project44. Both ports have been coping with disruptive COVID restrictions for months.

Nearby manufacturing hubs in Vietnam and Cambodia are already suffering from a shortage of Chinese components for their manufacturing industries, project44 reported. And pharmaceutical companies in India, which source 70% of their active ingredients from China, are facing limited supplies.

Ocean shipping delays from the top three Chinese ports to Hamburg, Germany, and Amsterdam had already doubled to more than 12 days during the first quarter, before the Shanghai lockdown fully materialized, according to project44 data.

Ocean freight expert Lars Jensen, CEO of Vespucci Maritime, summed up the situation on his LinkedIn page this way: “Until this situation is resolved — which appears next to impossible when matching the omicron variant with zero-tolerance — we should expect drops in export demand, port omissions and more blank sailings in the near term future as well as Shanghai-bound cargo increasingly being discharged elsewhere.”

COVID lockdowns spread

Meanwhile, COVID infections are spreading beyond Shanghai, according to news reports and logistics companies. The southern manufacturing hub of Guangzhou, for example, has started mass COVID testing, introduced travel restrictions and shifted schools to online learning — steps that often portend a wider lockdown.

The city of Kunshan — an important production center for electronics near Shanghai — is closed down until April 19. Part of Taicang, another manufacturing area in Jiangsu province, is also locked down. A surge of new COVID cases is hitting the coastal cities of Dalian and Tianjin in the north, Ningbo in the east, and Xiamen and Dongguan in the south.

Ningbo officials ordered residents in two downtown districts to sequester at home, but so far the seaport is not affected. Nantong is on a partial lockdown until April 15. Port operations have been severely impacted, with logistics companies diverting shipments to Nanjing. Zhangiagang is also under partial lockdown until April 19, resulting in slower port operations and some factory closures.

Many shippers are exercising contingency plans and using alternative import/export gateways when possible, but road transport is increasingly difficult.

The outbreaks have led to a virtual ban by authorities on truck drivers from high- and medium-risk areas transporting cargo to low-risk areas. That includes transporting cargo from Shanghai and Kunshan to the Port of Ningbo. No cargo will be accepted if drivers have been to medium- or high-risk areas within the last 14 days or the factory is located in medium- or high-risk areas, said UPS Supply Chain Solutions in a customer update.

As of Friday, Dalian, Tianjin, parts of Beijing, Shanghai, and Dongguan are all in high- and medium-risk areas.

Dimerco said in a notice that traffic control for road transportation is getting more strict and it is difficult to secure trucks to bring freight to Shanghai or alternative ports.

Lockdowns ease U.S. supply chain strains before flood of cargo

The slowdown in China exports should provide temporary relief to congestion-plagued U.S. ports on both coasts, as well as in Europe, but logistics experts say the breather is likely to be followed by a tsunami of deferred cargo once the lockdowns are lifted. The cargo volume will far exceed the handling capability of the ports, with containers jamming up terminals faster than they can be transferred to inland transport and pushing vessels into long queues at sea.

Delta Air LInes President Glen Hauenstein said on an earnings call Wednesday that once the Shanghai restrictions are lifted, the airline expects a boom in cargo bookings that more than offsets the current export lag.

A mass quarantine that lasts until June could mean the drawdown of backlogged air and ocean freight pushes into the peak shipping season, as more volume enters the system.

“Even with air and ocean ports open, the length of the shutdown could make this iteration the most significant logistics disruption since the start of the pandemic,” Freightos said in its update.

International

Red Candle In The Wind

Red Candle In The Wind

By Benjamin PIcton of Rabobank

February non-farm payrolls superficially exceeded market expectations on Friday by…

By Benjamin PIcton of Rabobank

February non-farm payrolls superficially exceeded market expectations on Friday by printing at 275,000 against a consensus call of 200,000. We say superficially, because the downward revisions to prior months totalled 167,000 for December and January, taking the total change in employed persons well below the implied forecast, and helping the unemployment rate to pop two-ticks to 3.9%. The U6 underemployment rate also rose from 7.2% to 7.3%, while average hourly earnings growth fell to 0.2% m-o-m and average weekly hours worked languished at 34.3, equalling pre-pandemic lows.

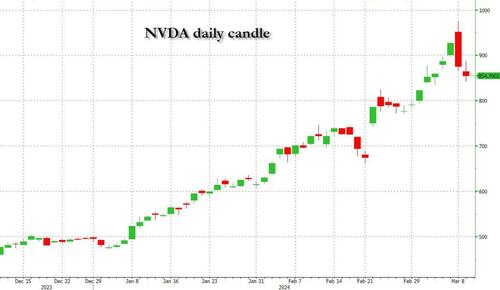

Undeterred by the devil in the detail, the algos sprang into action once exchanges opened. Market darling NVIDIA hit a new intraday high of $974 before (presumably) the humans took over and sold the stock down more than 10% to close at $875.28. If our suspicions are correct that it was the AIs buying before the humans started selling (no doubt triggering trailing stops on the way down), the irony is not lost on us.

The 1-day chart for NVIDIA now makes for interesting viewing, because the red candle posted on Friday presents quite a strong bearish engulfing signal. Volume traded on the day was almost double the 15-day simple moving average, and similar price action is observable on the 1-day charts for both Intel and AMD. Regular readers will be aware that we have expressed incredulity in the past about the durability the AI thematic melt-up, so it will be interesting to see whether Friday’s sell off is just a profit-taking blip, or a genuine trend reversal.

AI equities aside, this week ought to be important for markets because the BTFP program expires today. That means that the Fed will no longer be loaning cash to the banking system in exchange for collateral pledged at-par. The KBW Regional Banking index has so far taken this in its stride and is trading 30% above the lows established during the mini banking crisis of this time last year, but the Fed’s liquidity facility was effectively an exercise in can-kicking that makes regional banks a sector of the market worth paying attention to in the weeks ahead. Even here in Sydney, regulators are warning of external risks posed to the banking sector from scheduled refinancing of commercial real estate loans following sharp falls in valuations.

Markets are sending signals in other sectors, too. Gold closed at a new record-high of $2178/oz on Friday after trading above $2200/oz briefly. Gold has been going ballistic since the Friday before last, posting gains even on days where 2-year Treasury yields have risen. Gold bugs are buying as real yields fall from the October highs and inflation breakevens creep higher. This is particularly interesting as gold ETFs have been recording net outflows; suggesting that price gains aren’t being driven by a retail pile-in. Are gold buyers now betting on a stagflationary outcome where the Fed cuts without inflation being anchored at the 2% target? The price action around the US CPI release tomorrow ought to be illuminating.

Leaving the day-to-day movements to one side, we are also seeing further signs of structural change at the macro level. The UK budget last week included a provision for the creation of a British ISA. That is, an Individual Savings Account that provides tax breaks to savers who invest their money in the stock of British companies. This follows moves last year to encourage pension funds to head up the risk curve by allocating 5% of their capital to unlisted investments.

As a Hail Mary option for a government cruising toward an electoral drubbing it’s a curious choice, but it’s worth highlighting as cash-strapped governments increasingly see private savings pools as a funding solution for their spending priorities.

Of course, the UK is not alone in making creeping moves towards financial repression. In contrast to announcements today of increased trade liberalisation, Australian Treasurer Jim Chalmers has in the recent past flagged his interest in tapping private pension savings to fund state spending priorities, including defence, public housing and renewable energy projects. Both the UK and Australia appear intent on finding ways to open up the lungs of their economies, but government wants more say in directing private capital flows for state goals.

So, how far is the blurring of the lines between free markets and state planning likely to go? Given the immense and varied budgetary (and security) pressures that governments are facing, could we see a re-up of WWII-era Victory bonds, where private investors are encouraged to do their patriotic duty by directly financing government at negative real rates?

That would really light a fire under the gold market.

Government

Trump “Clearly Hasn’t Learned From His COVID-Era Mistakes”, RFK Jr. Says

Trump "Clearly Hasn’t Learned From His COVID-Era Mistakes", RFK Jr. Says

Authored by Jeff Louderback via The Epoch Times (emphasis ours),

President…

Authored by Jeff Louderback via The Epoch Times (emphasis ours),

President Joe Biden claimed that COVID vaccines are now helping cancer patients during his State of the Union address on March 7, but it was a response on Truth Social from former President Donald Trump that drew the ire of independent presidential candidate Robert F. Kennedy Jr.

During the address, President Biden said: “The pandemic no longer controls our lives. The vaccines that saved us from COVID are now being used to help beat cancer, turning setback into comeback. That’s what America does.”

President Trump wrote: “The Pandemic no longer controls our lives. The VACCINES that saved us from COVID are now being used to help beat cancer—turning setback into comeback. YOU’RE WELCOME JOE. NINE-MONTH APPROVAL TIME VS. 12 YEARS THAT IT WOULD HAVE TAKEN YOU.”

An outspoken critic of President Trump’s COVID response, and the Operation Warp Speed program that escalated the availability of COVID vaccines, Mr. Kennedy said on X, formerly known as Twitter, that “Donald Trump clearly hasn’t learned from his COVID-era mistakes.”

“He fails to recognize how ineffective his warp speed vaccine is as the ninth shot is being recommended to seniors. Even more troubling is the documented harm being caused by the shot to so many innocent children and adults who are suffering myocarditis, pericarditis, and brain inflammation,” Mr. Kennedy remarked.

“This has been confirmed by a CDC-funded study of 99 million people. Instead of bragging about its speedy approval, we should be honestly and transparently debating the abundant evidence that this vaccine may have caused more harm than good.

“I look forward to debating both Trump and Biden on Sept. 16 in San Marcos, Texas.”

Mr. Kennedy announced in April 2023 that he would challenge President Biden for the 2024 Democratic Party presidential nomination before declaring his run as an independent last October, claiming that the Democrat National Committee was “rigging the primary.”

Since the early stages of his campaign, Mr. Kennedy has generated more support than pundits expected from conservatives, moderates, and independents resulting in speculation that he could take votes away from President Trump.

Many Republicans continue to seek a reckoning over the government-imposed pandemic lockdowns and vaccine mandates.

President Trump’s defense of Operation Warp Speed, the program he rolled out in May 2020 to spur the development and distribution of COVID-19 vaccines amid the pandemic, remains a sticking point for some of his supporters.

Operation Warp Speed featured a partnership between the government, the military, and the private sector, with the government paying for millions of vaccine doses to be produced.

President Trump released a statement in March 2021 saying: “I hope everyone remembers when they’re getting the COVID-19 Vaccine, that if I wasn’t President, you wouldn’t be getting that beautiful ‘shot’ for 5 years, at best, and probably wouldn’t be getting it at all. I hope everyone remembers!”

President Trump said about the COVID-19 vaccine in an interview on Fox News in March 2021: “It works incredibly well. Ninety-five percent, maybe even more than that. I would recommend it, and I would recommend it to a lot of people that don’t want to get it and a lot of those people voted for me, frankly.

“But again, we have our freedoms and we have to live by that and I agree with that also. But it’s a great vaccine, it’s a safe vaccine, and it’s something that works.”

On many occasions, President Trump has said that he is not in favor of vaccine mandates.

An environmental attorney, Mr. Kennedy founded Children’s Health Defense, a nonprofit that aims to end childhood health epidemics by promoting vaccine safeguards, among other initiatives.

Last year, Mr. Kennedy told podcaster Joe Rogan that ivermectin was suppressed by the FDA so that the COVID-19 vaccines could be granted emergency use authorization.

He has criticized Big Pharma, vaccine safety, and government mandates for years.

Since launching his presidential campaign, Mr. Kennedy has made his stances on the COVID-19 vaccines, and vaccines in general, a frequent talking point.

“I would argue that the science is very clear right now that they [vaccines] caused a lot more problems than they averted,” Mr. Kennedy said on Piers Morgan Uncensored last April.

“And if you look at the countries that did not vaccinate, they had the lowest death rates, they had the lowest COVID and infection rates.”

Additional data show a “direct correlation” between excess deaths and high vaccination rates in developed countries, he said.

President Trump and Mr. Kennedy have similar views on topics like protecting the U.S.-Mexico border and ending the Russia-Ukraine war.

COVID-19 is the topic where Mr. Kennedy and President Trump seem to differ the most.

Former President Donald Trump intended to “drain the swamp” when he took office in 2017, but he was “intimidated by bureaucrats” at federal agencies and did not accomplish that objective, Mr. Kennedy said on Feb. 5.

Speaking at a voter rally in Tucson, where he collected signatures to get on the Arizona ballot, the independent presidential candidate said President Trump was “earnest” when he vowed to “drain the swamp,” but it was “business as usual” during his term.

John Bolton, who President Trump appointed as a national security adviser, is “the template for a swamp creature,” Mr. Kennedy said.

Scott Gottlieb, who President Trump named to run the FDA, “was Pfizer’s business partner” and eventually returned to Pfizer, Mr. Kennedy said.

Mr. Kennedy said that President Trump had more lobbyists running federal agencies than any president in U.S. history.

“You can’t reform them when you’ve got the swamp creatures running them, and I’m not going to do that. I’m going to do something different,” Mr. Kennedy said.

During the COVID-19 pandemic, President Trump “did not ask the questions that he should have,” he believes.

President Trump “knew that lockdowns were wrong” and then “agreed to lockdowns,” Mr. Kennedy said.

He also “knew that hydroxychloroquine worked, he said it,” Mr. Kennedy explained, adding that he was eventually “rolled over” by Dr. Anthony Fauci and his advisers.

MaryJo Perry, a longtime advocate for vaccine choice and a Trump supporter, thinks votes will be at a premium come Election Day, particularly because the independent and third-party field is becoming more competitive.

Ms. Perry, president of Mississippi Parents for Vaccine Rights, believes advocates for medical freedom could determine who is ultimately president.

She believes that Mr. Kennedy is “pulling votes from Trump” because of the former president’s stance on the vaccines.

“People care about medical freedom. It’s an important issue here in Mississippi, and across the country,” Ms. Perry told The Epoch Times.

“Trump should admit he was wrong about Operation Warp Speed and that COVID vaccines have been dangerous. That would make a difference among people he has offended.”

President Trump won’t lose enough votes to Mr. Kennedy about Operation Warp Speed and COVID vaccines to have a significant impact on the election, Ohio Republican strategist Wes Farno told The Epoch Times.

President Trump won in Ohio by eight percentage points in both 2016 and 2020. The Ohio Republican Party endorsed President Trump for the nomination in 2024.

“The positives of a Trump presidency far outweigh the negatives,” Mr. Farno said. “People are more concerned about their wallet and the economy.

“They are asking themselves if they were better off during President Trump’s term compared to since President Biden took office. The answer to that question is obvious because many Americans are struggling to afford groceries, gas, mortgages, and rent payments.

“America needs President Trump.”

Multiple national polls back Mr. Farno’s view.

As of March 6, the RealClearPolitics average of polls indicates that President Trump has 41.8 percent support in a five-way race that includes President Biden (38.4 percent), Mr. Kennedy (12.7 percent), independent Cornel West (2.6 percent), and Green Party nominee Jill Stein (1.7 percent).

A Pew Research Center study conducted among 10,133 U.S. adults from Feb. 7 to Feb. 11 showed that Democrats and Democrat-leaning independents (42 percent) are more likely than Republicans and GOP-leaning independents (15 percent) to say they have received an updated COVID vaccine.

The poll also reported that just 28 percent of adults say they have received the updated COVID inoculation.

The peer-reviewed multinational study of more than 99 million vaccinated people that Mr. Kennedy referenced in his X post on March 7 was published in the Vaccine journal on Feb. 12.

It aimed to evaluate the risk of 13 adverse events of special interest (AESI) following COVID-19 vaccination. The AESIs spanned three categories—neurological, hematologic (blood), and cardiovascular.

The study reviewed data collected from more than 99 million vaccinated people from eight nations—Argentina, Australia, Canada, Denmark, Finland, France, New Zealand, and Scotland—looking at risks up to 42 days after getting the shots.

Three vaccines—Pfizer and Moderna’s mRNA vaccines as well as AstraZeneca’s viral vector jab—were examined in the study.

Researchers found higher-than-expected cases that they deemed met the threshold to be potential safety signals for multiple AESIs, including for Guillain-Barre syndrome (GBS), cerebral venous sinus thrombosis (CVST), myocarditis, and pericarditis.

A safety signal refers to information that could suggest a potential risk or harm that may be associated with a medical product.

The study identified higher incidences of neurological, cardiovascular, and blood disorder complications than what the researchers expected.

President Trump’s role in Operation Warp Speed, and his continued praise of the COVID vaccine, remains a concern for some voters, including those who still support him.

Krista Cobb is a 40-year-old mother in western Ohio. She voted for President Trump in 2020 and said she would cast her vote for him this November, but she was stunned when she saw his response to President Biden about the COVID-19 vaccine during the State of the Union address.

“I love President Trump and support his policies, but at this point, he has to know they [advisers and health officials] lied about the shot,” Ms. Cobb told The Epoch Times.

“If he continues to promote it, especially after all of the hearings they’ve had about it in Congress, the side effects, and cover-ups on Capitol Hill, at what point does he become the same as the people who have lied?” Ms. Cobb added.

“I think he should distance himself from talk about Operation Warp Speed and even admit that he was wrong—that the vaccines have not had the impact he was told they would have. If he did that, people would respect him even more.”

International

There will soon be one million seats on this popular Amtrak route

“More people are taking the train than ever before,” says Amtrak’s Executive Vice President.

While the size of the United States makes it hard for it to compete with the inter-city train access available in places like Japan and many European countries, Amtrak trains are a very popular transportation option in certain pockets of the country — so much so that the country’s national railway company is expanding its Northeast Corridor by more than one million seats.

Related: This is what it's like to take a 19-hour train from New York to Chicago

Running from Boston all the way south to Washington, D.C., the route is one of the most popular as it passes through the most densely populated part of the country and serves as a commuter train for those who need to go between East Coast cities such as New York and Philadelphia for business.

Veronika Bondarenko

Amtrak launches new routes, promises travelers ‘additional travel options’

Earlier this month, Amtrak announced that it was adding four additional Northeastern routes to its schedule — two more routes between New York’s Penn Station and Union Station in Washington, D.C. on the weekend, a new early-morning weekday route between New York and Philadelphia’s William H. Gray III 30th Street Station and a weekend route between Philadelphia and Boston’s South Station.

More Travel:

- A new travel term is taking over the internet (and reaching airlines and hotels)

- The 10 best airline stocks to buy now

- Airlines see a new kind of traveler at the front of the plane

According to Amtrak, these additions will increase Northeast Corridor’s service by 20% on the weekdays and 10% on the weekends for a total of one million additional seats when counted by how many will ride the corridor over the year.

“More people are taking the train than ever before and we’re proud to offer our customers additional travel options when they ride with us on the Northeast Regional,” Amtrak Executive Vice President and Chief Commercial Officer Eliot Hamlisch said in a statement on the new routes. “The Northeast Regional gets you where you want to go comfortably, conveniently and sustainably as you breeze past traffic on I-95 for a more enjoyable travel experience.”

Here are some of the other Amtrak changes you can expect to see

Amtrak also said that, in the 2023 financial year, the Northeast Corridor had nearly 9.2 million riders — 8% more than it had pre-pandemic and a 29% increase from 2022. The higher demand, particularly during both off-peak hours and the time when many business travelers use to get to work, is pushing Amtrak to invest into this corridor in particular.

To reach more customers, Amtrak has also made several changes to both its routes and pricing system. In the fall of 2023, it introduced a type of new “Night Owl Fare” — if traveling during very late or very early hours, one can go between cities like New York and Philadelphia or Philadelphia and Washington. D.C. for $5 to $15.

As travel on the same routes during peak hours can reach as much as $300, this was a deliberate move to reach those who have the flexibility of time and might have otherwise preferred more affordable methods of transportation such as the bus. After seeing strong uptake, Amtrak added this type of fare to more Boston routes.

The largest distances, such as the ones between Boston and New York or New York and Washington, are available at the lowest rate for $20.

stocks pandemic japan european-

Uncategorized3 weeks ago

Uncategorized3 weeks agoAll Of The Elements Are In Place For An Economic Crisis Of Staggering Proportions

-

Uncategorized3 weeks ago

Uncategorized3 weeks agoCalifornia Counties Could Be Forced To Pay $300 Million To Cover COVID-Era Program

-

International4 days ago

International4 days agoEyePoint poaches medical chief from Apellis; Sandoz CFO, longtime BioNTech exec to retire

-

Uncategorized2 weeks ago

Uncategorized2 weeks agoApparel Retailer Express Moving Toward Bankruptcy

-

Uncategorized4 weeks ago

Uncategorized4 weeks agoIndustrial Production Decreased 0.1% in January

-

International3 days ago

International3 days agoWalmart launches clever answer to Target’s new membership program

-

Uncategorized3 weeks ago

Uncategorized3 weeks agoRFK Jr: The Wuhan Cover-Up & The Rise Of The Biowarfare-Industrial Complex

-

Uncategorized3 weeks ago

Uncategorized3 weeks agoGOP Efforts To Shore Up Election Security In Swing States Face Challenges